Page 5 - qp_14

P. 5

MAKMAL KESIHATAN AWAM KOTA BHARU

Document Number : MKAKB/BP/QP-14

QUALITY PROCEDURE

Issue Number : 01

MANAGEMENT OF REAGENT AND Issue Date : 03.04.2016

CONSUMABLES Page Number : 2 of 5

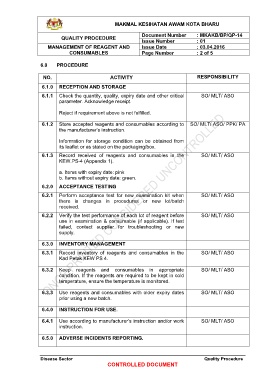

6.0 PROCEDURE

NO. ACTIVITY RESPONSIBILITY

6.1.0 RECEPTION AND STORAGE

6.1.1 Check the quantity, quality, expiry date and other critical SO/ MLT/ ASO

parameter. Acknowledge receipt.

Reject if requirement above is not fulfilled.

6.1.2 Store accepted reagents and consumables according to SO/ MLT/ ASO/ PPK/ PA

the manufacturer’s instruction.

Information for storage condition can be obtained from

its leaflet or as stated on the packaging/box.

6.1.3 Record received of reagents and consumables in the SO/ MLT/ ASO

KEW.PS-4 (Appendix 1).

a. Items with expiry date: pink

b. Items without expiry date: green.

6.2.0 ACCEPTANCE TESTING

6.2.1 Perform acceptance test for new examination kit when SO/ MLT/ ASO

there is changes in procedures or new lot/batch

received.

6.2.2 Verify the test performance of each lot of reagent before SO/ MLT/ ASO

use in examination & consumable (if applicable). If test

failed, contact supplier for troubleshooting or new

supply.

6.3.0 INVENTORY MANAGEMENT

6.3.1 Record inventory of reagents and consumables in the SO/ MLT/ ASO

Kad Petak KEW PS 4.

6.3.2 Keep reagents and consumables in appropriate SO/ MLT/ ASO

condition. If the reagents are required to be kept in cold

temperature, ensure the temperature is monitored.

6.3.3 Use reagents and consumables with older expiry dates SO/ MLT/ ASO

prior using a new batch.

6.4.0 INSTRUCTION FOR USE.

6.4.1 Use according to manufacturer’s instruction and/or work SO/ MLT/ ASO

instruction.

6.5.0 ADVERSE INCIDENTS REPORTING.

Disease Sector Quality Procedure

CONTROLLED DOCUMENT